FlexiMod offers a simple concept to integrate custom solutions for electrohydraulic applications, while main-taining the advantages of continuous deliverability of standard solutions and the individuality of customer-specific designs.

Under the guiding principle “parameterization instead of programming”, W.E.St. Elektronik GmbH has developed the script-based concept, “FlexiMod” which eases the implementation of customer-specific functions in a commonly available product line. The concept is based on a standardized hardware architecture with a core of basic control functions and a flexible engine that complements the base with user defined operations. Due to the simplicity of the script-based engine, there are almost no programming skills required to compose custom solutions.

In its basic configuration all input signals like process and setpoint values are simply mapped 1-to-1 to the available outputs, either analogue outputs or the power stage output directly controlling the valve.

The actual function for meaningful processing of the signals can be freely defined by the script. No programming knowledge or experience with common PLC programming languages is required. The script editor is clearly divided into rows and columns, with each row basically reflecting the result of an operation and each column defining the input signals of the operation. These are then processed cyclically line by line from top to bottom.

The script provides logic operators, time functions and mathematical operators as well as some special func-tions. With this it is possible to extend functionality from generating a simple saw tooth signal profile to more complex tasks, such as closed loop controls.

We also offer variants that already provide a basic functionality as factory default, for example for positioning control. This basically allows to immediately get into the customization part of the design by implementing individual operations within the pre-set control function without having to implement the baseline positioning task first.

The script environment “WestScript” is available as a free download. It allows online and offline configuration as well as simulation. The integrated oscilloscope tracks the signal curves of up to 4 different operations offline during implementation or online during com-missioning and operation. So that the behavior can be validated and, if necessary, be adjusted prior or during commissioning and maintenance.

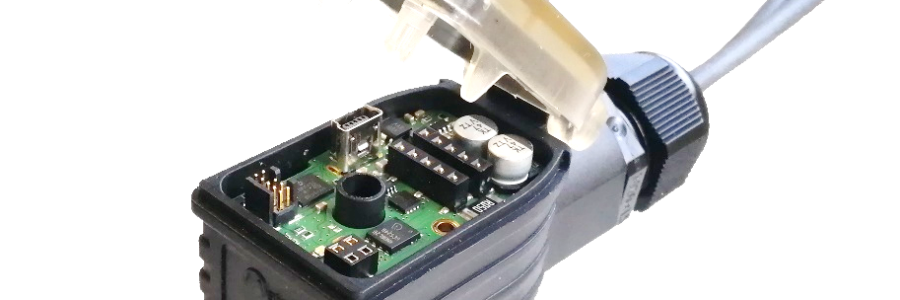

The hardware architecture of the new series offers a new core with higher processing power that allows a constant cycle time of not more than 1ms, independ-ent of the length of the script. FlexiMod is a platform-based solution and re-uses expansions of our current platforms, so that we can provide e.g. derivatives with or without power output stage or network connectivity from stock. The base comes with analog and digital inputs/outputs which can be assigned flexibly to process and setpoint signals via the configuration in the script. That means that, that in many cases, additional PLC hardware such as analogue I/O units are no longer necessary.

When individual solutions are requested, they are usually provided as order-based engineering service by component manufacturers or implemented in a PLC program at high efforts. In both cases, the related expenses in terms of cost and time to implement the function as well as the requirements related to HW performance and expertise of the implementing per-sonal are not insignificant. It is not unusual that it takes months. In contrast, the effort involved in script de-velopment is reduced to days or maybe a few weeks. W.E.St. Elektronik offers both the service to develop scripts for customers upon request and the assistance/guidance for customers developing their own script. It is also possible to get an OEM version of the product, which already has the individual configuration on board as factory default.

Due to its flexibility and adaptability FlexiMod can be considered the swiss-army-knife of electrohydraulic controls that can be utilized to execute many differ-ent control tasks. It is ideal e.g. as functional replacement for control units when machines are renewed or repaired to reproduce the previous functionality with a more contemporary solution.

An advantage that system integrators and/or machine builders typically benefit from is that with just a few catalog numbers, different configurations can be mapped, which are integrated into different variants of your systems/machines. At the same time, the logistics related to procurement and warehousing become easier, since only one hardware basis must be kept on stock instead of different derivatives.

The first devices with the FlexiMod Engine are DSG-112-U, with analog outputs, and DSG-112-P, with power output stage for direct control of valve mag-nets. They are completely free configurable and pro-vide the full FlexiMod capability.